Bolt Eżagonali tal-Azzar tal-Karbonju Din 933

| Isem tal-prodotti | BOLT EŻAGONALI TAL-AZZAR TAL-KARBONJU DIN 933/ISO4017 |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Grad | Grad tal-Azzar: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Irfinar | Żingu (Isfar, Abjad, Blu, Iswed), Galvanizzat bil-Hop Dip (HDG), Ossidu Iswed, Ġeomet, Dakroment, anodizzazzjoni, indurat bin-nikil, indurat bin-żingu-nikil |

| Proċess ta' Produzzjoni | M2-M24: Żrinġ Kiesaħ, Forġar bis-Sħun M24-M100, Makkinar u CNC għal qafliet personalizzati |

| Ħin taċ-Ċomb tal-Prodotti Personalizzati | 30-60 jum, |

| Kampjuni b'xejn għal qafla standard | |

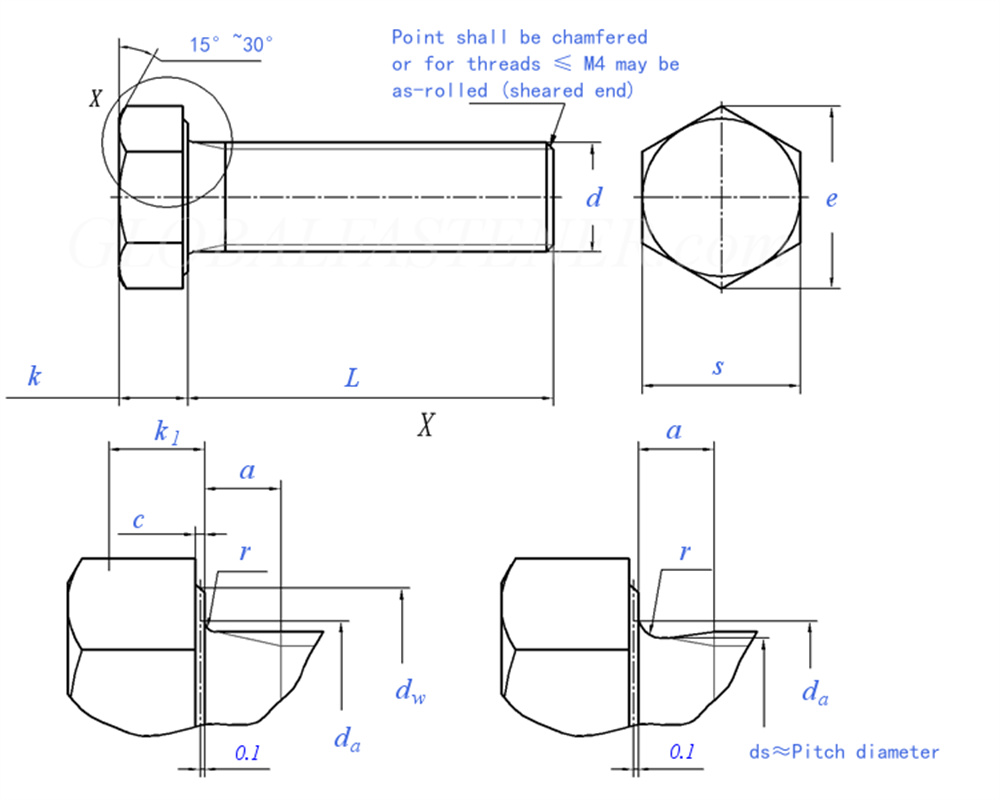

| Ħajt tal-viti | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Żift | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | massimu | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| minuta | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | massimu | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| minuta | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | massimu | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | Grad A | minuta | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Grad B | minuta | 2.3 | 2.95 | 3.95 | 4.45 | 4.95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Grad A | minuta | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Grad B | minuta | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Daqs Nominali | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Grad A | massimu | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| minuta | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Grad B | massimu | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| minuta | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Grad A | minuta | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Grad B | minuta | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | minuta | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | massimu = daqs nominali | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Grad A | minuta | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Grad B | minuta | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ħajt tal-viti | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Żift | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | massimu | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| minuta | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | massimu | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| minuta | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | massimu | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | Grad A | minuta | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Grad B | minuta | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Grad A | minuta | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Grad B | minuta | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Daqs Nominali | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Grad A | massimu | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| minuta | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Grad B | massimu | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| minuta | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Grad A | minuta | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Grad B | minuta | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | minuta | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | massimu = daqs nominali | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Grad A | minuta | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Grad B | minuta | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ħajt tal-viti | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Żift | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | massimu | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| minuta | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | massimu | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| minuta | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | massimu | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | Grad A | minuta | - | - | - | - | - | - | ||||||

| Grad B | minuta | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | Grad A | minuta | - | - | - | - | - | - | ||||||

| Grad B | minuta | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Daqs Nominali | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| Grad A | massimu | - | - | - | - | - | - | |||||||

| minuta | - | - | - | - | - | - | ||||||||

| Grad B | massimu | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| minuta | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | Grad A | minuta | - | - | - | - | - | - | ||||||

| Grad B | minuta | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | minuta | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | massimu = daqs nominali | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| Grad A | minuta | - | - | - | - | - | - | |||||||

| Grad B | minuta | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Karatteristiċi u Benefiċċji

Bolt Eżagonali tal-Azzar tal-Karbonju Din 933: Is-Soluzzjoni għall-Bżonnijiet ta' Twaħħil Tiegħek

Meta niġu għall-irbit, trid soluzzjoni li tkun robusta, affidabbli u faċli biex tinstalla. Il-Bolt Eżagonali tal-Azzar tal-Karbonju Din 933 jissodisfa l-bżonnijiet kollha billi joffri bolt durabbli u versatili li jista' jintuża f'firxa wiesgħa ta' applikazzjonijiet.

Magħmul minn azzar tal-karbonju ta' kwalità għolja, dan il-bolt huwa ddisinjat biex jiflaħ ambjenti iebsa, stress għoli u tagħbijiet tqal. Ir-ras eżagonali tipprovdi twaħħil sigur u strett, filwaqt li l-kamin jippermetti installazzjoni u tneħħija faċli.

B'tul ta' bejn 6mm u 100mm, dan il-bolt huwa disponibbli f'firxa ta' daqsijiet biex jaqdi proġetti u rekwiżiti differenti. Kemm jekk qed tibni magna, twaqqaf struttura jew twaħħal tagħmir flimkien, dan il-bolt joffri s-saħħa u r-reżiljenza li għandek bżonn biex twettaq ix-xogħol.

Barra minn hekk, il-Bolt Eżagonali tal-Azzar tal-Karbonju Din 933 huwa faċli biex jinżamm u ma jiddeterjorax faċilment maż-żmien. Dan ifisser li tista' tiddependi fuq l-effettività tiegħu għal snin wara l-installazzjoni.

Għal dawk li qed ifittxu bolt li huwa kemm affordabbli kif ukoll ta’ kwalità għolja, dan il-bolt tal-azzar tal-karbonju huwa għażla perfetta. Mhux biss jelimina l-ħtieġa għal soluzzjonijiet ta’ twaħħil għaljin u kkumplikati, iżda huwa wkoll faċli biex jiġi installat u mneħħi, u b’hekk jiffrankalek ħin u sforz prezzjuż.

Fil-qosor, Carbon Steel Hex Bolt Din 933 hija soluzzjoni ta' twaħħil affidabbli ħafna u prattika li tista' tintuża f'firxa ta' applikazzjonijiet. Hija ddisinjata għal durabilità massima u faċilità ta' użu, u b'hekk hija għażla ideali kemm għall-inġiniera, il-bennejja kif ukoll għad-dilettanti tad-DIY. Afda f'Carbon Steel Hex Bolt Din 933 biex jipprovdilek soluzzjoni li tissodisfa l-bżonnijiet kollha, irrispettivament minn liema proġett qed taħdem fuqu.